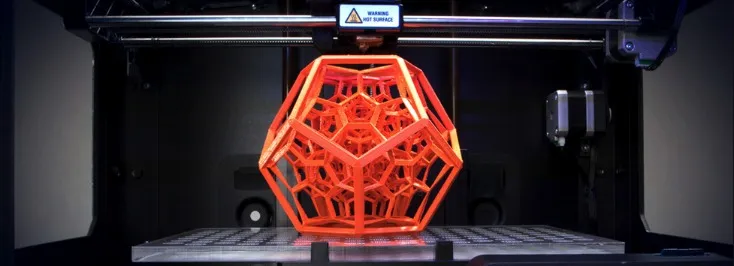

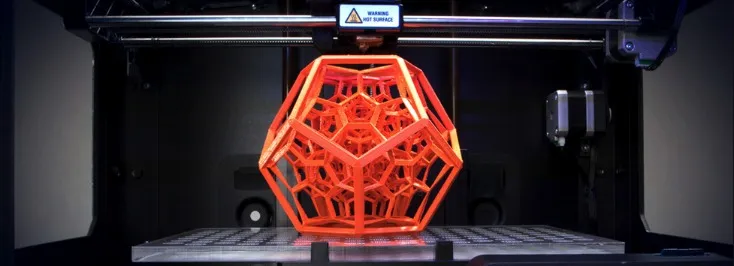

3D Printers: The Future of Manufacturing

Did you know...? 3D printing has been put to use to create almost every imaginable object from car parts and camera lenses to candy and artificial organs. The technology was invented by American engineer Charles Hull in 1984 and has quickly been embraced by the aerospace, automotive and manufacturing industries, which use it to build parts more cost efficiently.

Last week a Russian 3D printing construction company built the first ever on-site printed house. The move triggered a lively debate on whether 3D printers will become the future of manufacturing. Let’s see what has already been achieved in 3D printing and how the innovative technology can be

Houses

The first 3D printed house built completely on-site was brought to life by the Apis Cor 3D Construction company and Russian public developer PIK. The building looks like a normal one-storey cottage with an unusual design - the house is in the shape of a rotor. It was made from a concrete mixture topped with a weather-resistant roof. 3D printing had been

Fighter Jet Parts

In 2014, combat vehicle manufacturer BAE Systems launched the first British fighter jets with parts made using 3D printers into the skies. Since then, 3D printing has been continuously

Organs

Believe it or not, 3D printers can create bones, skin, kidneys, blood vessels and other organs - a fact proven by scientists who have saved the lives of many people by replacing their organs with 3D printed body parts. The medical “bioprinters” use a special gel-like substance made from the patient’s cells. However, bones are made of ceramic powder. Hopefully, in the near

Car Parts

General Motors and Ford were among the first automotive companies to adopt 3D printing in car manufacturing. In 2014 GM used 3D printing to save time spent on part prototyping for their new Chevrolet Malibu. To be more specific, they used stereolithography and laser sintering controlled by special software with mathematical data. Ford in turn widely uses 3D printers to manufacture parts such as brake rotors, vents, cylinder heads and shift knobs. If you drive a Ford Explorer, then you should know that many details of your vehicle were made by 3D printers. As for the title of first 3D printed car, this belongs to the Strati electrical car developed by American company Local Motors. It took 44 hours to print the vehicle, which was followed by three days of assembling until the car could finally take its first test drive.

3D printing is a promising technology which can replace many forms of traditional manufacturing. In the coming